Home / Statistical Tools / QFD, FMEA, & Pugh / FMEA / FMEA Overview

FMEA Overview¶

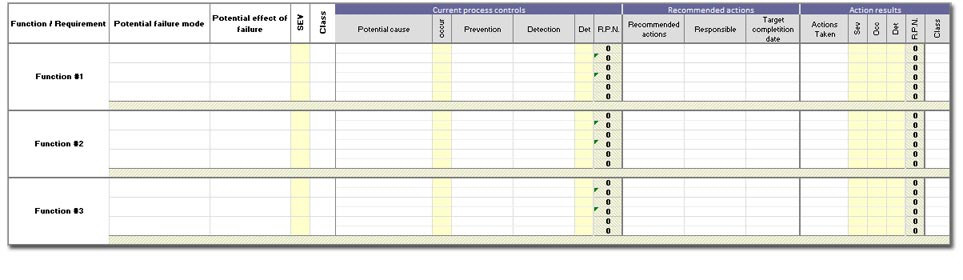

Failure Mode and Effects Analysis (FMEA) is a procedure to identify potential failure modes for a product or process.

FMEA is used to identify potential failure modes, determine their effect on the operation of the product, and identify actions to mitigate the failures. It is widely used in the manufacturing industries in various phases of the product life cycle.

Failure causes are any errors or defects in process, design, or item, especially ones that affect the customer.

Rating columns exist for the severity of effects of failure, probability of failure and the effectiveness of the design validation. These ratings are multiplied together to achieve a risk priority number (RPN). Rating numbers typically range from one to ten, with higher numbers designating unacceptable conditions.